Brochure

Get a Quote

Fill all information details to consult with us to get sevices from us

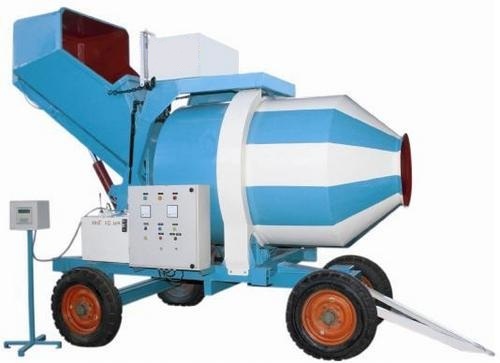

ABOUT 10/7 HYDRO CONCRETE MIXER

BM arrangement of 10/7 Hydro Concrete Mixer are the best one bag concrete mixer and is utilized to blend concrete, sand and different aggregates to deliver concrete of the necessary evaluation.

A 10/7 Hydro concrete mixer machine is a machine that mixes cement, aggregate (such as sand or gravel), and water to form concrete in a uniform manner. It is commonly referred to as a concrete mixer. Batching machines are important in the construction company. It is used to combine cement, materials such as sand and gravel, and water to create high-quality concrete and a solid foundation for structures.

The B. M. Engineering can provide customers with a handmade concrete mixing machine. Although this heavy machinery is able to produce enormous amounts of high-quality concrete in a short period of time, this leading construction machine exporter also offers tiny concrete mixers, saving you time and money.

Applications: Mixing of cement on building destinations.

- Hydraulic Concrete Mixer 10/7 Features

- Digital Accurate Load Cell based gauging framework

- Double Bin powerfully worked container

- Automatic Water Pump

- Heavy Duty Cast Iron Drum empowers simple shifting of drum subsequently decreasing weariness for the labourer and expanding yield extensively.

- Special stage gave on working side to helpful and safe activity of the machine.

- Tire Axle with locking framework

- Brand New Pneumatic Tires

- Heavy Duty M.S. Channel Chassis

Technical Specification of Hydro Concrete Mixer

| MODEL NO. | BM 100 MIXH |

| Capacity | Unmixed : 10 cft. Blended: 7 cft. |

| Volume | 450 Litres |

| Prime Mover | 7.5 HP air cooled HSD diesel motor/5 HP 3 stage Electric Motor |

| Hopper | Hopper 3.15 mm thick M.S. container using pressurized water worked with rock solid force pack. |

| Hydraulic System | Single Action Hydraulic Jack. Single Spool with physically worked control valve, henceforth simple to work with any incompetent individual. ISI mark high constrain hoses to circle the oil |

| Wire Rope | Usha Martin 10 mm – 6×36 |

| Drum Speed | 18 rpm |

| Wheels | Brand new 500 x 19 pneumatic tire with center point and bearing framework, and squeezed steel plate edges – 4 Nos |

| Handy Yoke | 100x100x5 mm C Section M.S. channel, Bearing System |

| Chassis | Heavy Duty M.S. 125 x 65 mm Channel undercarriage furnished with jack on each of the four sides for leveling the machine. |

| Drive Chain | Rolon brand |

| Mixing Drum and Blades | Heavy Duty CI Lower drum 3.15 mm M.S. upper drum and hard core M.S. sharp edges for blending |

| Drum Type | Tilting |

| Motor Cabin | 16 G (1.6 mm) Thick |

| Dimensions MM | L 2640 x W 2060 x H 2960 MM |

| Weight | 1360 kg |